(Dịnamic) Vacuum mkpuchi mkpuchi(Na-agbanwe agbanwe)Sistemụ ọkpọkọ, Vacuum Insulated Valves na Vacuum Phase Separators dị mkpa maka nrụpụta, nnwale ngwaahịa na ikuku dị ọcha dị oke elu na ụlọ ọrụ elektrọn & ụlọ nrụpụta.Ngwa HL Cryogenic nwere ahụmịhe afọ 20 na ụlọ ọrụ elektrọn & ụlọ nrụpụta.Achịkọbara ọtụtụ ahụmahụ na ihe ọmụma, na ikike nke "ịchọpụta nsogbu ndị ahịa", "edozi nsogbu ndị ahịa" na "imelite usoro ndị ahịa".Nsogbu ndị a na-ahụkarị gụnyere,

- (Na akpaaka) Mgbanwe nke ahịrị isi na alaka

- Mgbanwe nrụgide (Mbelata) yana kwụsie ike nke VIP

- Okpomọkụ nke Nitrogen Liquid n'ime ngwa ngwa

- Oke ezi uche dị na ya nke ikuku ikuku Cryogenic

- Na-ehichapụ ihe adịghị ọcha na ihe fọdụrụ na ice site na tankị

- Oge ndochi nke akụrụngwa Liquid Terminal

- Pipeline Precooling

- Nguzogide Liquid na Sistemu VIP

- Jikwaa mfu nke Nitrogen Liquid N'oge Ọrụ Akwụsịghị nke Sistemu

Ewubere HL's Vacuum Insulated Pipe (VIP) ka ọ bụrụ koodu ASME B31.3 Pressure Piping dị ka ọkọlọtọ.Ahụmahụ injinia na ikike njikwa mma iji hụ na arụmọrụ na ọnụ ahịa nke osisi ndị ahịa.

Ngwaahịa ndị emetụtara

Ndị ahịa ama ama

- Huawei

- Osram Light

- Samsung

- Intel

- Isi mmalite Photonics

- SMC

- Tencent

- Foxconn

Ngwọta

HL Cryogenic Equipment na-enye ndị ahịa na Vacuum Insulated Piping Sistem iji mezuo ihe achọrọ na ọnọdụ nke ụlọ ọrụ elektrọn & n'ichepụta:

1.Quality Management System: ASME B31.3 Piping Code.

2.Reasonable design and placement of Phase Separator na VI Piping System bụ isi ihe iji hụ na nkwụsi ike na afọ ojuju nke nrụgide mmiri na okpomọkụ.

3. A na-etinye ihe mgbochi mmiri nke gas na ọkpọkọ VI kwụ ọtọ na njedebe nke VI pipeline.Ihe mgbochi mmiri mmiri nke gas na-eji ụkpụrụ akara gas na-egbochi okpomọkụ site na njedebe nke pipeline VI n'ime VI Piping, ma belata n'ụzọ dị irè na-efunahụ nitrogen mmiri mmiri n'oge nkwụsịtụ na nkwụsịtụ nke usoro ahụ.

4.Cleanliness, ma ọ bụrụ na e nwere ndị ọzọ chọrọ maka n'ime tube elu ịdị ọcha.A na-atụ aro ka ndị ahịa na-ahọrọ ọkpọkọ igwe anaghị agba nchara BA ma ọ bụ EP dị ka ọkpọkọ VIP dị n'ime iji belata nchara igwe anaghị agba nchara.

5.Vacuum Insulated Filter: Na-ehichapụ ihe ndị na-adịghị mma na ihe fọdụrụ na ice site na tank.

6.VI Pipe Controlled by The Vacuum Insulated Valve (VIV) Series: Gụnyere Vacuum Insulated (Pneumatic) Mechie Valve, Vacuum Insulated Check Valve, Vacuum Insulated Regulating Valve etc. Dị iche iche nke VIV nwere ike ịbụ modular jikọtara iji chịkwaa VIP dị ka. achọrọ.Ejikọtara VIV na prefabrication VIP na ndị nrụpụta, na-enweghị ọgwụgwọ mkpuchi na saịtị.Enwere ike dochie nkeji akara nke VIV ngwa ngwa.(HL na-anabata akara valvụ cryogenic nke ndị ahịa họpụtara, wee mee ka HL na-eme ka valvụ ndị na-ekpo ọkụ na-ekpo ọkụ. Ụfọdụ ụdị na ụdị valves nwere ike ọ gaghị enwe ike ịme ka ọ bụrụ valvụ mkpuchi mkpuchi.)

7.After a ụbọchị ole na ole ma ọ bụ ogologo shutdown ma ọ bụ mmezi, ọ dị ezigbo mkpa ka precool na VI Piping na ọnụ akụrụngwa tupu cryogenic mmiri mmiri abanye, ka zere ice slag mgbe cryogenic mmiri mmiri ozugbo abanye VI pipeing na ọnụ akụrụngwa.Ekwesịrị ịtụle ọrụ precooling na imewe.Ọ na-enye nchebe ka mma maka akụrụngwa ọnụ na akụrụngwa nkwado VI dị ka valves.

8.Suit maka ma Dynamic na Static Vacuum Insulated (Flexible) Piping System.

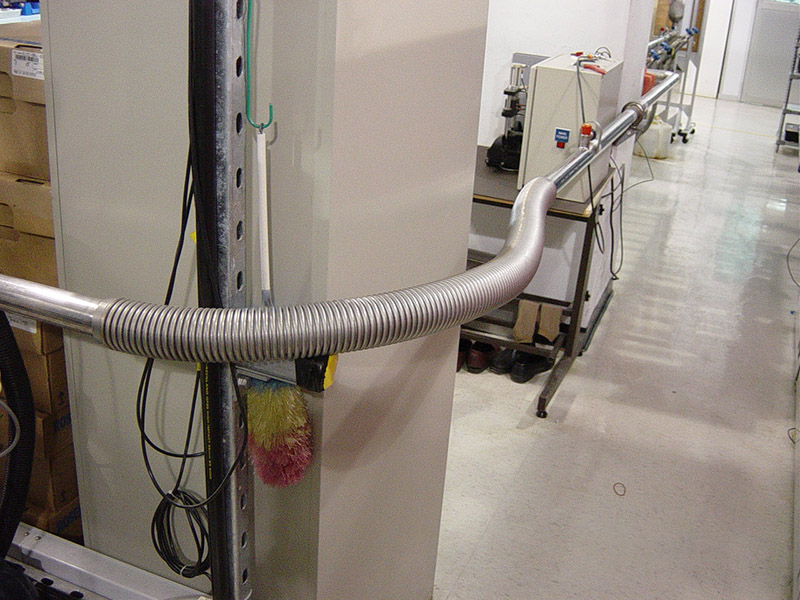

9.Dynamic Vacuum Insulated (Mgbanwe) Piping System: mejupụtara VI Flexible Hoses na / ma ọ bụ VI Pipe, Jumper Hoses, Vacuum Insulated Valve System, Phase Separators na Dynamic Vacuum Pump System (gụnyere mgbapụta mgbapụta, valvụ solenoid na oghere oghere wdg. ).Enwere ike ịhazi ogologo nke otu VI Flexible Hose dịka ihe onye ọrụ chọrọ.

10. Ụdị Njikọ dị iche iche: Vacuum Bayonet Connection (VBC) Ụdị na Njikọ Welded nwere ike ịhọrọ.Ụdị VBC adịghị mkpa ọgwụgwọ mkpuchi na saịtị.